枪钻直径范围: 1.00-12.00 | 最大钻孔深度: 550mm

整体硬质合金枪钻是由钻身(钻尖与钻杆一体)、钻柄两部分通过焊接成一个整体,也可以为全部整体硬质合金制做而成 (钻尖、钻杆、钻柄 一体) ,它的稳定性、效率以及寿命均优于焊接式。 这种设计能够保证更高的可靠性和切削性能,同时它较高的刚性和较低的扭曲振动可以使刀具寿命更长。

| 规格 | 外形尺寸 (mm) |

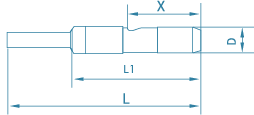

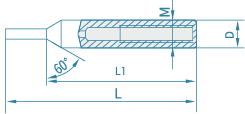

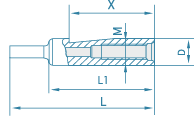

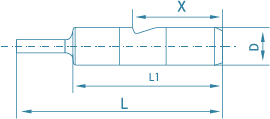

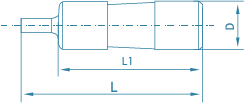

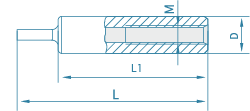

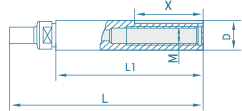

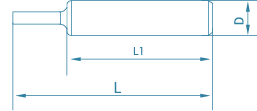

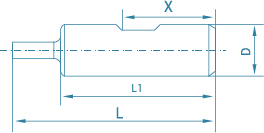

简图 | 刀具长度计算 | 定位槽 X |

螺纹规格 M |

|

| L1 | L | |||||

| SH6-03 | 6 |  |

30 | 45 | 17 | |

| SH10-15 | 10 |  |

55 | 70 | M6×0.5 | |

| SH10-37 | 10 |  |

40 | 55 | M6×0.5 | |

| SH10-42 | 10 |  |

40 | 55 | 24 | |

| SH12.7-01 | 12.7 |  |

38 | 48 | 24 | |

| SH12.7-09 | 12.7 |  |

51 | 65 | M6×0.5 | |

| SH16-75 | 16 |  |

80 | 105 | 37 | M10×1 |

| SH4-08 | 4 |  |

34 | 46 | ||

| SH6-12 | 6 | 36 | 50 | |||

| SH10-51 | 10 | 40 | 55 | |||

| SH12-27 | 12 | 45 | 60 | |||

| SH16-86 | 16 | 48 | 63 | |||

| SH6-13 | 6 |  |

36 | 50 | 20 | |

| SH10-47 | 10 | 40 | 55 | 23.5 | ||

| SH12-30 | 12 | 45 | 60 | 26.5 | ||

| SH16-78 | 16 | 48 | 63 | 29 | ||

| SH6-01 | 6 |  |

36 | 50 | 25 | |

| SH10-49 | 10 | 40 | 55 | 28 | ||

| SH12-28 | 12 | 45 | 60 | 33 | ||

| SH16-84 | 16 | 48 | 63 | 36 | ||

| 整体硬质合金库存表 | ||

| ¢1.52*160-10*55 | ¢2.0*250-10*135 | ¢3.8*185-4*38/50-L |

| ¢1.80*160-10*55 | ¢2.2*170-4*38/50 | ¢3.8*240-10*100-L |

| ¢2.02*160-10*55 | ¢2.5*175-4*38/50-L | ¢3.8*275-10*135-L |

| ¢2.02*180-10*55 | ¢2.5*230-10*100-L | ¢4.0*185-4*38/50-L |

| ¢2.02*180-10*55-L | ¢2.5*265-10*135-L | ¢4.0*240-10*100-L |

| ¢2.02*200-10*55 | ¢2.6*175-4*38/50-L | ¢4.0*275-10*135-L |

| ¢2.02*200-10*55-L | ¢2.6*265-10*135-L | ¢4.2*185-4*38/50-L |

| ¢2.52*180-10*55 | ¢2.8*175-4*38/50-L | ¢4.2*240-10*100-L |

| ¢2.52*180-10*55-L | ¢2.8*265-10*135-L | ¢4.2*275-10*135-L |

| ¢3.02*180-10*55 | ¢3.0*175-4*38/50-L | ¢4.5*285-10*135-L |

| ¢3.02*200-10*55 | ¢3.0*230-10*100-L | ¢4.8*250-10*100-L |

| ¢3.02*200-10*55-L | ¢3.0*265-10*135-L | ¢5.0*250-10*100-L |

| ¢2.8*170-2.9*30-L | ¢3.2*180-4*38/50-L | ¢5.0*260-10*100-L |

| ¢3.0*170-2.9*30-L | ¢3.2*230-10*100-L | ¢6.0*260-10*100-L |

| ¢3.2*170-3.1*30-L | ¢3.2*265-10*135-L | ¢6.0*295-10*135-L |

| ¢1.80*200-10*100 | ¢3.5*180-4*38/50-L | ¢7.0*280-10*100-L |

| ¢2.0*170-4*38/50 | ¢3.5*230-10*100-L | ¢9.0*280-10*100-L |

| ¢2.0*220-10*100 | ¢3.5*265-10*135-L | ¢10.0*280-10*100-L |