焊接式枪钻包含焊接式单刃枪钻和焊接式双刃枪钻。焊接式单刃枪钻是由钻尖、钻杆和钻柄三部分通过焊接成为一个整体,可根据被加工材料的不同选择不用牌号的硬质合金材料进行合理的刀具设计。钻头通常采用整体硬质合金,刀头部分与经过热处理的钻杆钎焊在一起,然后再与精磨过的钢制钻柄进行钎焊链接。对于特殊材料也可以通过不同种类的涂层来应对。

焊接式双刃枪钻有两个对称的切削刃,与单刃枪钻有着相同的切削液循环系统,切削液有刀头上的两个进油孔供入切削刃部,切削液和切削的混合物由刀杆外部的排屑槽排除。双刃枪钻是由钻尖、钻杆、钻柄三部分通过焊接成为一个整体,也可以为全整体硬质合金制作而成。但由于双刃钻的排屑空间有限,因此它适用于加工易断屑材料。

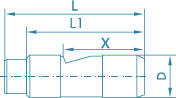

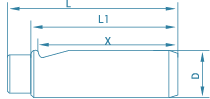

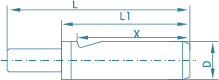

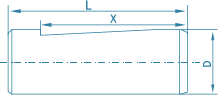

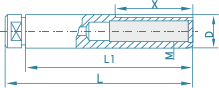

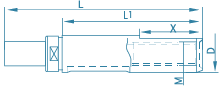

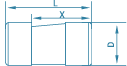

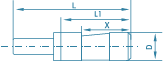

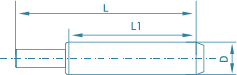

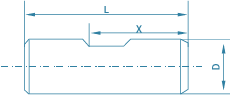

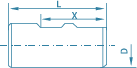

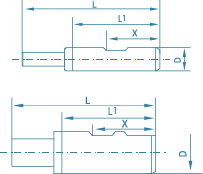

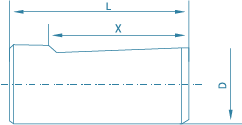

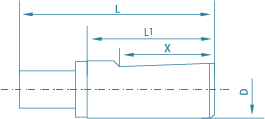

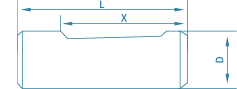

| 规格 | 外形尺寸

(mm) |

简图 | 刀具长度计算 | 定位槽

X |

螺纹规格 M |

|

| L1 | L | |||||

| SH10-00 | 10 |  |

40 | 24.0 | ||

| SH16-03 | 16 | 45 | 53 | 31.0 | ||

| SH25-00 | 25 | 70 | 78 | 34.0 | ||

| SH10-01 | 10 |  |

40 | 57 | 24.0 | |

| SH16-04 | 16 | 45 | 72 | 31.0 | ||

| SH25-01 | 25 |  |

70 | 105 | 34.0 | |

| SH16-02 | 16 |  |

50 | 58 | 47.5 | |

| SH16-33 | 16 |  |

50 | 77 | 47.5 | |

| SH10-06 | 10 |  |

60 | M6×0.5 | ||

| SH16-15 | 16 | 80 | M10×1 | |||

| SH25-08 | 25 | 100 | M16×1.5 | |||

| SH10-28 | 10 |  |

60 | 77 | M6×0.5 | |

| SH16-22 | 16 | 80 | 104 | M10×1 | ||

| SH25-10 | 25 | 100 | 140 | M16×1.5 | ||

| SH12.7-00 | 12.7 |  |

38.01 | 25.03 | ||

| SH19.05-01 | 19.05 | 70 | 45.0 | |||

| SH25.4-00 | 25.4 | 70 | 57.5 | |||

| SH31.7-00 | 31.7 | 70 | 57.5 | |||

| SH38.1-00 | 38.1 | 70 | 57.5 | |||

| SH19.05-11 | 19.05 |  |

70 | 97 | 45.0 | |

| SH25.4-11 | 25.4 | 70 | 100 | 57.5 | ||

| SH31.7-01 | 31.7 | 70 | 110 | 57.5 | ||

| SH38.1-01 | 38.1 | 70 | 110 | 57.5 | ||

| SH10-44 | 10 |  |

60 | 68 | 35 | M6×0.5 |

| SH16-31 | 16 | 80 | 90 | 37 | M10×1 | |

| SH25-34 | 25 | 100 | 112 | 45 | M16×1.5 | |

| SH16-66 | 16 |  |

80 | 110 | 37 | M10×1 |

| SH25-40 | 25 | 100 | 142 | 45 | M16×1.5 | |

| SH10-30 | 10 |  |

40 | 57 | 28.0 | |

| SH12-14 | 12 | 45 | 62 | 33.0 | ||

| SH16-70 | 16 | 48 | 75 | 36.0 | ||

| SH20-56 | 20 | 50 | 77 | 38.0 | ||

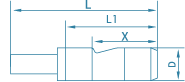

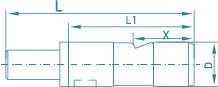

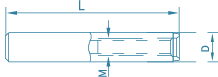

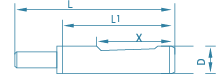

| Specification | Diameter

(mm) |

Drawing | Length Calculation | Fix Position

X |

Screw Spec M |

|

| L1 | L | |||||

| SH16-00 | 16 |  |

112 | 73.0 | TR16×1.5 | |

| SH20-00 | 20 | 126 | 82.0 | TR20×2 | ||

| SH28-00 | 28 | 126 | 82.0 | TR28×2 | ||

| SH36-00 | 36 | 162 | 109.0 | TR36×2 | ||

| SH16-21 | 16 |  |

40 | 28.0 | ||

| SH25-16 | 25 | 50 | 35.0 | |||

| SH35-00 | 35 | 60 | 40.0 | |||

| SH16-30 | 16 |  |

40 | 67 | 28.0 | |

| SH25-20 | 24 | 50 | 77 | 35.0 | ||

| SH35-01 | 35 | 60 | 100 | 40.0 | ||

| SH10-40 | 10 |  |

40 | |||

| SH12-18 | 12 | 45 | ||||

| SH16-11 | 16 | 48 | ||||

| SH20-01 | 20 | 50 | ||||

| SH25-11 | 25 | 56 | ||||

| SH32-24 | 32 | 60 | ||||

| SH40-03 | 40 | 70 | ||||

| SH10-41 | 10 |  |

40 | 57 | ||

| SH12-19 | 12 | 45 | 62 | |||

| SH16-20 | 16 | 48 | 75 | |||

| SH20-60 | 20 | 50 | 77 | |||

| SH25-21 | 25 | 56 | 86 | |||

| SH32-23 | 32 | 60 | 100 | |||

| SH40-04 | 40 | 70 | 110 | |||

| SH10-11 | 10 |  |

40 | 23.5 | ||

| SH12-07 | 12 | 45 | 26.5 | |||

| SH16-32 | 16 | 48 | 29.0 | |||

| SH20-29 | 20 | 50 | 30.5 | |||

| SH25-22 | 25 |  |

56 | 38.0 | ||

| SH32-10 | 32 | 60 | 43.0 | |||

| SH40-13 | 40 | 70 | 47.0 | |||

| SH10-23 | 10 |  |

40 | 57 | 23.5 | |

| SH12-02 | 12 | 45 | 62 | 26.5 | ||

| SH16-53 | 16 | 48 | 75 | 29.0 | ||

| SH20-34 | 20 | 50 | 77 | 30.5 | ||

| SH25-31 | 25 | 56 | 86 | 38.0 | ||

| SH32-11 | 32 | 60 | 100 | 43.0 | ||

| SH40-14 | 40 | 70 | 110 | 47.0 | ||

| SH10-20 | 10 |  |

40 | 28.0 | ||

| SH12-08 | 12 | 45 | 33.0 | |||

| SH16-47 | 16 | 48 | 36.0 | |||

| SH20-40 | 20 | 50 | 38.0 | |||

| SH25-36 | 25 | 56 | 44.0 | |||

| SH32-12 | 32 | 60 | 48.0 | |||

| SH40-18 | 40 | 70 | 66.0 | |||

| SH10-24 | 10 |  |

40 | 57 | 28.0 | |

| SH12-05 | 12 | 45 | 62 | 33.0 | ||

| SH16-51 | 16 | 48 | 75 | 36.0 | ||

| SH20-43 | 20 | 50 | 77 | 38.0 | ||

| SH25-37 | 25 | 56 | 86 | 44.0 | ||

| SH32-13 | 32 | 60 | 100 | 48.0 | ||

| SH40-17 | 40 | 70 | 110 | 66.0 | ||

| SH10-29 | 10 |  |

40 | 28.0 | ||

| SH12-13 | 12 | 45 | 33.0 | |||

| SH16-62 | 16 | 48 | 36.0 | |||

| SH20-55 | 20 | 50 | 38.0 | |||

| 焊接式单刃枪钻库存表 | ||||||||||||

| 规格 | 235mm | 270mm | 刀柄 | 800 mm | 1000 mm | 1200 mm | 1440 mm | 1650 mm | 1800 mm | 刀柄 | ||

| 标准 | 涂层 | 标准 | 涂层 | |||||||||

| φ3.02 | ● | ● | 10*40

16*48 |

● | ● | 25*78 | ||||||

| φ3.52 | ● | ● | ● | ● | ||||||||

| φ4.02 | ● | ● | ● | ● | ● | |||||||

| φ4.52 | ● | ● | ● | ● | ● | |||||||

| φ5.02 | ● | ● | ● | ● | ● | ● | ● | |||||

| φ5.52 | ● | ● | ● | ● | ● | ● | ● | |||||

| φ6.02 | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| φ6.52 | ● | ● | ● | ● | ● | ● | ● | |||||

| φ7.02 | ● | ● | ● | ● | ● | ● | ● | |||||

| φ7.52 | ● | ● | ● | ● | ● | ● | ||||||

| φ8.02 | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| φ8.52 | ● | ● | ● | ● | ● | ● | ||||||

| φ9.02 | ● | ● | ● | ● | ● | ● | ● | |||||

| φ9.52 | ● | ● | ● | ● | ● | ● | ||||||

| φ10.02 | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| φ10.52 | ● | ● | ● | ● | ● | ● | ||||||

| φ11.02 | ● | ● | ● | ● | ● | ● | ||||||

| φ11.52 | ● | ● | ● | ● | ● | |||||||

| φ12.02 | ● | ● | ● | ● | ● | ● | ● | |||||